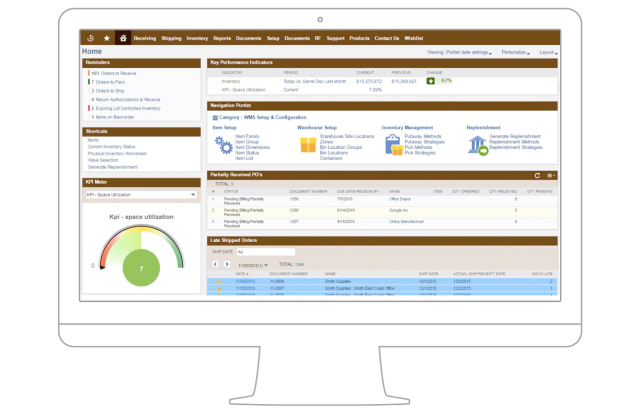

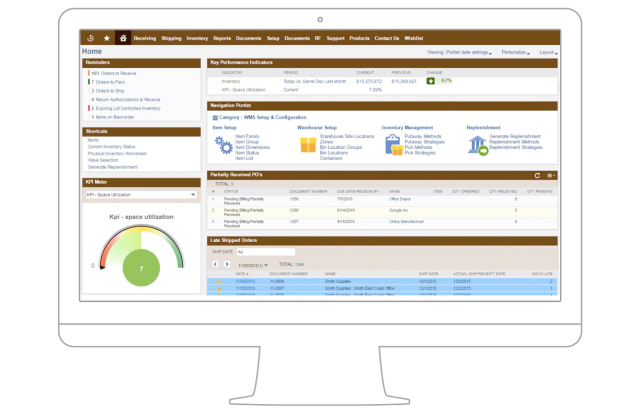

NetSuite Warehouse Management System (WMS) optimizes day-to-day warehouse operations using industry-leading practices, such as mobile RF barcode scanning, defined strategies for putaway and picking, task management, return authorization receipts and cycle count plans. With hundreds or even thousands of SKUs to handle, often across multiple locations, warehouse management can quickly become a manual, chaotic and inefficient process if you're relying on spreadsheets — or worse, pen and paper. NetSuite WMS eliminates manual processes, allowing you to minimize handling costs, run your warehouses more efficiently and consistently meet customer expectations.